Page 2 of 6

Re: My homebrew picks...finally!

Posted:

Sun Jun 05, 2011 1:45 pmby Bryanxwhite

So I was wandering around home depot this past Friday looking for some ideas for pick handles. I made my way to the electrical isle and found some heavy duty heat shrink tubing. I believe it's an insulated type. It's about 1/16" thick and 1/2" diameter. Once it's shrunk down it ends up being 1/4" thick and will go down to 1/4" diameter. I used some fish tape metal to reinforce the handle and shrunk it down onto the pick handle. It turned out quite well, very sturdy and comfortable. There's no give in it once it's shrunk to the handle. It gives really good feedback and is a good looking black plastic look to it. I'll post some pics a little later.

Re: My homebrew picks...finally!

Posted:

Sun Jun 05, 2011 2:52 pmby Oldfast

Very nice! Thanks for posting the pictures.

Re: My homebrew picks...finally!

Posted:

Sun Jun 05, 2011 6:06 pmby piotr

Well done! They look good.

Re: Bryanxwhite's Home Brew

Posted:

Sun Jun 19, 2011 5:41 pmby Bryanxwhite

I've been trying to research ways to secure g-10 to picks without using epoxy. It would allow me to replace a pick should it ever break. I found a website

http://www.hawkinsknifemakingsupplies.com and found threaded barrels and such designed to mount knife handles to the blades. It seems like it would work great with the proper counter boring. Has anyone used anything similar to this? I'm going to order some tomorrow and find out how well this actually works. With sizes ranging from 1/8" - 5/8" it should be very plausible to secure the g-10 or any other material to the pick if using a tap isnt possible.

Re: Bryanxwhite's Home Brew

Posted:

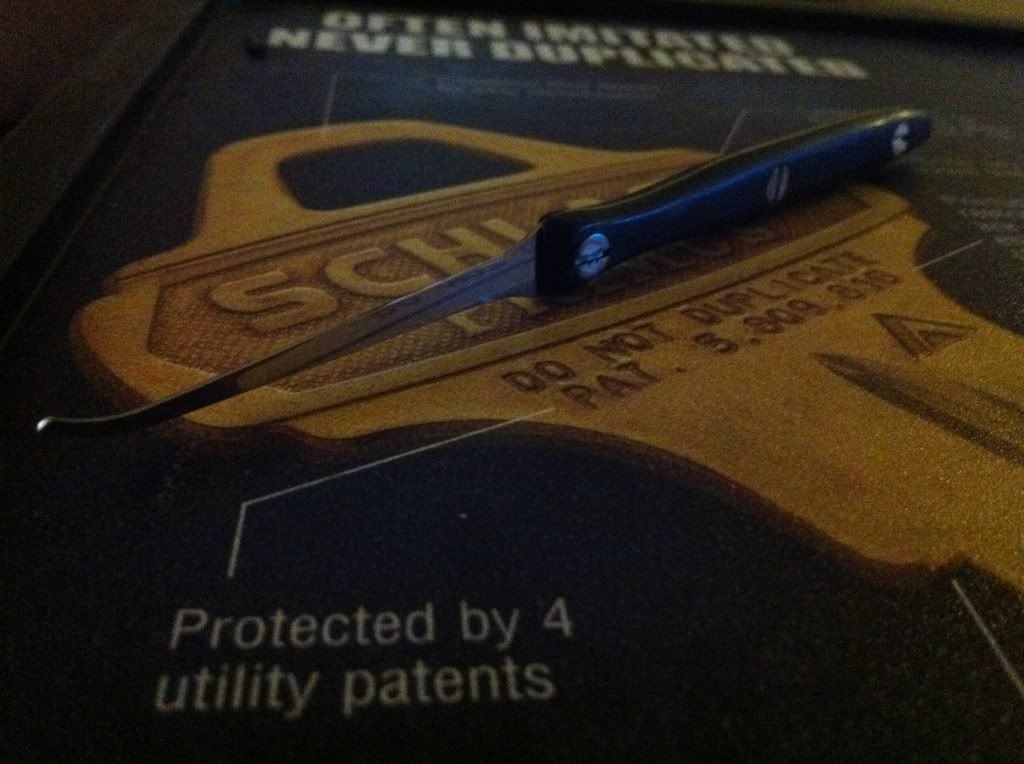

Tue Jun 21, 2011 6:17 pmby Bryanxwhite

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 7:10 pmby bezza1

holy fuck mate that looks awesome i want one lol great job it is super sexy

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 7:22 pmby chris

What did you use to shape the G10? I wish I could get mine to turn out that rounded and smooth.

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 7:39 pmby Bryanxwhite

Thanks Bezza! Chris, I used a Makita flex sander with 50 grit to rough shape, also made the curves with the 50. I used that heavy of grit to take down the metal from the pick so it was flush. If you use a lighter grit the metal will keep you from shaping the lesser material and just cause you to round off the g-10 inadvertently. (lots of experience fabricating granite). After the shaping it was on to the 120. 320, 400, 600(dry), 600(wet), 800(wet) then buff with cloth wheel and buffing compound. I love that 'corse' g-10 because when you round off areas you can see the different layers and it gives it a 'wood' grain affect.

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 8:09 pmby Oldfast

Holy !#%($&, lookin' good man. I'm eager to see more. Keep up the good work, and PLEASE, post more pictures as you go!

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 8:10 pmby chris

Ok so you had two even sized pieces at first, then you bolted them to the pick, then you started doing all the fabrication on sanding down the design and all that?

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 9:06 pmby Bryanxwhite

chris wrote:Ok so you had two even sized pieces at first, then you bolted them to the pick, then you started doing all the fabrication on sanding down the design and all that?

That's correct. In my experience it's the best way to get a seamless joint even with metal in between 2 soft mediums. 50 grit takes off the metal at the same rate as the g-10 as long as you have thin enough metal and stay 90 degrees to the piece.

Re: Bryanxwhite's Home Brew

Posted:

Tue Jun 21, 2011 9:07 pmby Bryanxwhite

Oldfast wrote:Holy !#%($&, lookin' good man. I'm eager to see more. Keep up the good work, and PLEASE, post more pictures as you go!

Thank you! I plan on working on some more this weekend. I'll take some pictures of the process this time.

Re: Bryanxwhite's Home Brew

Posted:

Fri Jun 24, 2011 7:40 pmby kulpnc001

That thing looks great man. You need to put together a set.

Do you have any unique/specialty tools?

Re: Bryanxwhite's Home Brew

Posted:

Mon Jul 11, 2011 5:23 pmby Bryanxwhite

I finished up this one this weekend. The next one I'm working on will be an identical one for LSA. I wanted to try out some 1/4" aluminum rod as rivets before sending one out. I try to make a 'test' pick when trying new things. I think it turned out alright. One problem I had was keeping the handle from shifting when I has securing the rod into the handles. The next one wont have any issues. Maybe hammering isn't the best way to go. Let me know what you guys think.

Re: Bryanxwhite's Home Brew

Posted:

Mon Jul 11, 2011 5:55 pmby chris

Again, very nice, is it G10? The handles I have made have been straight, I haven't tried using a sanding drum to add divots and such like yours. I may give it a shot. Did you just use a standard manual rivet gun to add those?