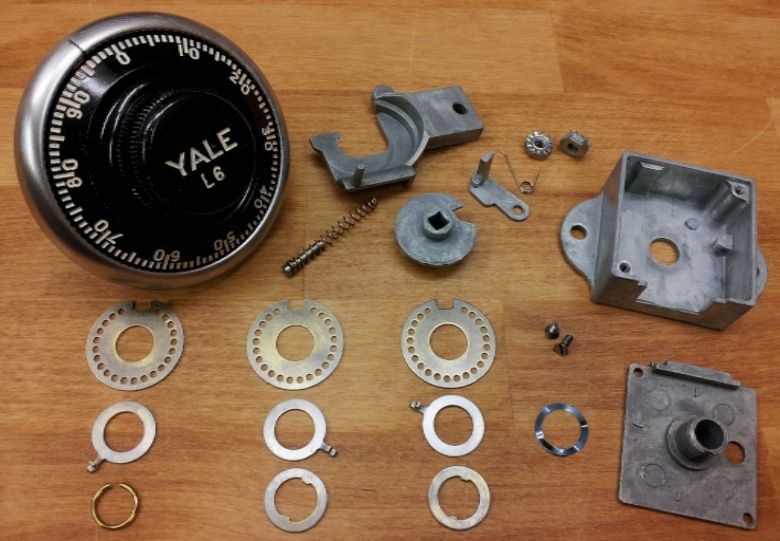

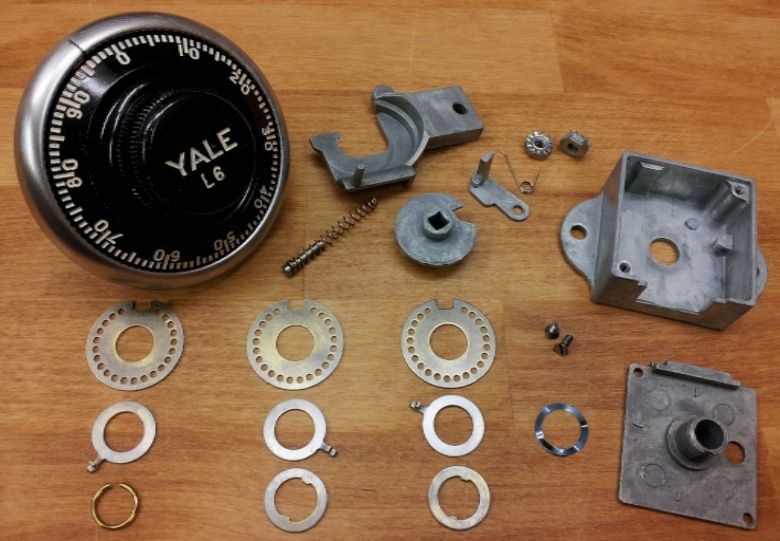

manipulation #26YaleGroup2 ... 3 wheel ... hole change ... spring-loaded fence

These are wee little locks that can sometimes pack quite a wallop. Normally found on small chests or strongboxes,

they're notoriously known for sloppy and inconsistent readings. This was evident after my first (and only) encounter

with one that pretty much kicked my ass for several days before finally opening it, lol. -

Manipulation#3. So I was all

too excited to have one for the lockroom. So much so I ended up paying probably more than twice what I should've.

CONTACT AREAApproximately 10 incs wideLCP

CONTACT AREAApproximately 10 incs wideLCP 73 . . . . .

RCP 83

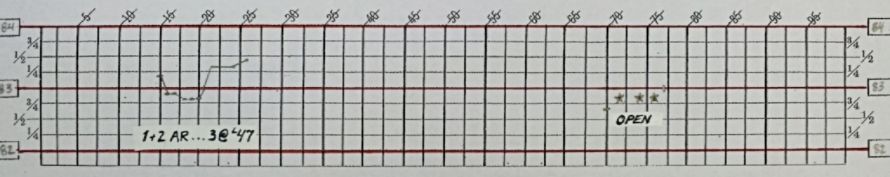

ROTATIONAL CONVERSIONpickup differences for wheels 3, 2, 1

5 .... 10 .... 15 .... respectively

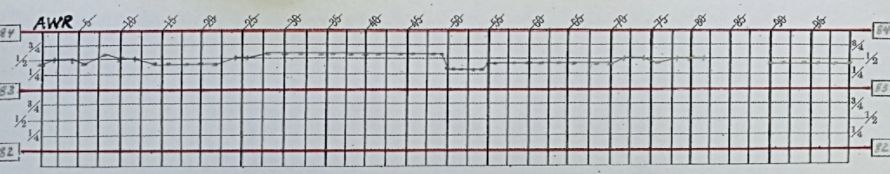

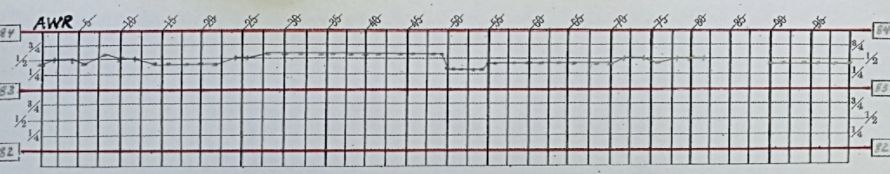

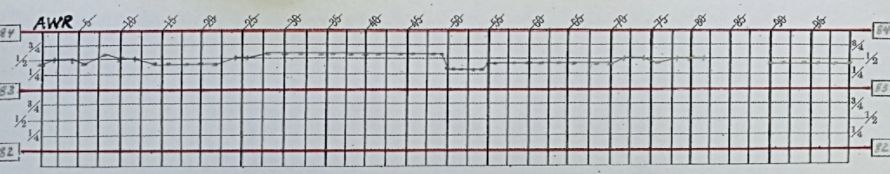

READINGSRIGHT contact point

ONLY...taken in

tenths every 2 incs

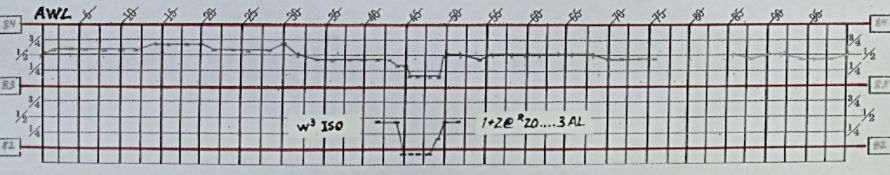

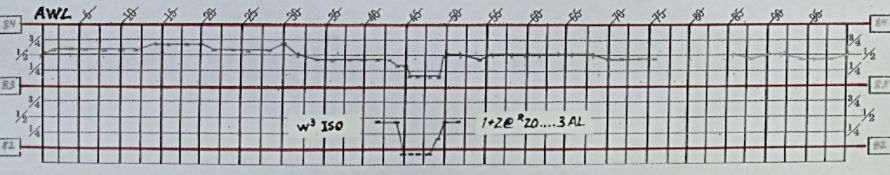

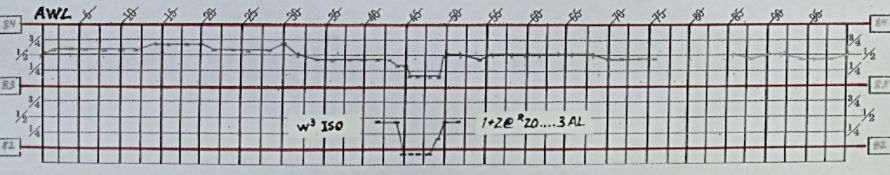

BINDING ORDER3 - 2 - 1UNKNOWN COMBOL74 - R19 - L46My preferred AWR rotation reveals a gate, 52. Rather than pursue this gate just yet, I decided to run

an AWL graph as well. Not the best decision timewise, but I was curious if it might reveal another gate.

Not much more shows up. But the same gate

does appear @

left 47 just as it did with

right rotation @ 52.

A difference of

exactly 5 incs - which correlates to wheel 3's pickup difference - a clue to the gate's owner.

I used isolation to verify this (

you can see this included in my 2nd graph). Referring back to my AWR graph,

I chose a semi-low area (R20) to park wheels 1&2 at. Then ran w3 through the are of 47. No doubt remains.

-

-  - L47Although I've successfully tagged this gate to w3, I wanted to take a moment to hopefully get a discussion going;

- L47Although I've successfully tagged this gate to w3, I wanted to take a moment to hopefully get a discussion going;

High/Low testing when working with fixed drive pins! The large pickup differences they create is a game-changer.

I'm gonna attempt to explain the way I see it (and you might want a dial nearby!) lol

This may help some of you. It may confuse the hell out of others. But MOST of all

I'm hoping it will prompt some constructive criticism from some of you veterans. Lets first take note of a couple things. Recall our pickup differences; w3=5.. w2=10.. w1=15

So if I park AWL @ our gate (47) then turned RIGHT picking up one wheel at a time;

w3 will pick up at 52. w2 picks up at 57. And w1 at 62. Just progressively add 5, ok?

So we've some #'s to remember: pickups 5, 10, 15. And our gate (+5) 47, 52, 57, 62.

Knowing this you'll see some problems occur with the traditional approach for testing.

A low test for example. Here we decide to 'throw' each wheel off by 5 increments.

So each wheel is tested by bringing it from the original gate at 47, down to 42.

L47 L47 R

42 L47 R

42 L47

R

42 L47 L47

In actuality wheels have been displaced much more than just 5 incs. And progressively so with each wheel.

w3 was thrown 10 incs. w2 by 15 incs. And w1 a whopping 20 incs. Look at w3; we begin moving it when it

initially picks up at 52 (

NOT 47). So by the time I bring it to 42, it's been pushed 10 incs off the gate. And at

the other end we have w1. Picks up at 62, way before reaching 47. Bring it to 42 and I've pushed it 20 incs.

Throwing the wheels by

different amounts is no good for consistency. And, throwing them by

such

large amounts could potentially place one on another gate, thoroughly diluting results.

The correct way, I

think, to handle this while accounting for the drive pins would be:

AWL @ 47 . . . 83.2L47 L47 R

47 . . . . .

83.4L47 R

52 L47 . . . . . 83.3

R

57 L47 L47 . . . . . 83.2

w3 picks up at

52. Continuing to

47 displaces it by

5 increments.

w2 picks up at

57. Continuing to

52 displaces it by

5 increments.

w1 picks up at

62. Continuing to

57 displaces it by

5 increments.

But again, this is just some of what I've been trying to work out. I'd love to hear some validation or criticism!Enough on that. Lets see about hearing that fence drop in! And it happened much sooner than I expected.

-

-  - L47

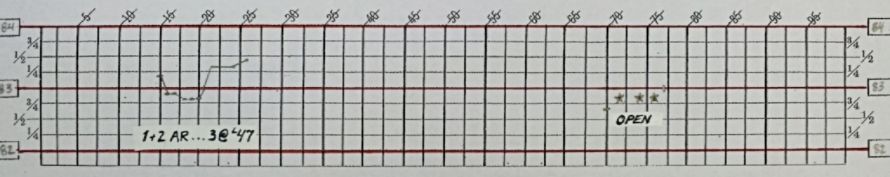

- L47With a known gate for w3, I'm now ready to run 1&2 AR while placing 3 on its' gate of L47.

But BEFORE I commit to an entire rotation of readings, I take a good look over my first two graphs.Is there ANY areas that are EVEN SLIGHTLY curious? If so, why not take a matter of seconds to explore them?!

If they materialize you've saved an enormous amount of time. If they don't (which is often the case), simply start

your full rotation, skipping any numbers or areas you've already tried. In this case... it paid off big... and quick.

I spot a couple areas worthy of my attention - at least briefly. Roughly 28-12 and 70-75.

1&2 through the area of 20 brings about a definite gate. But which wheel?

- R19 - L47

- R19 - L47Rather than attempting to tag it, I tentatively assume it's w2

while I send w1 over to dance around in the 70's.

BINGOOPEN: L72 - R19 - L47With little to no coaxing, the fence drops in at 72, 74, or 76.

. .. ... ... ....Final Thoughts.... ... ... .. .1

. .. ... ... ....Final Thoughts.... ... ... .. .1As far as the sloppy & inconsistent readings these locks are known for - I'm sure there's a variety of reasons.

Certainly

one of the contributing factors is the square spindle that seats loosely in the drive cam. This leaves

a small amount of play between the two parts rather than being solidly connected like a spline key would do.

In order minimize the effect this would have, I tried to 'max out' its' limit of movement before taking a reading.

ie. I'd make one or two abrupt movements in the direction of my contact point (prior to reaching it of course),

then slowly approach the contact point and take a reading. Naturally this extra movement was not needed if

I was approaching the contact area with left rotation - I could just continue left in order to touch the right CP,

and assume the spindle has likely moved within the cam as much as it's going to. But whenever I dropped

into the contact area with right rotation and had to switch directions to hit the RCP, I would give it a couple

snappy movements before reading the RCP. This may not even be necessary! More experimenting to go.

2One things for sure! This manipulation was insanely smooth in comparison to my encounter several years

ago with a similar lock. Of course, this lock is in stellar condition - thoroughly cleaned, lubed, and spinning

smooth and true. The other lock was in rough shape. Dirty, couple sticking points, and drag on one wheel.

3And lastly, (if I haven't already made it abundantly clear, lol) I'm up for any talk you'd like to have about

fixed drive pins. And not necessarily just about hi/low testing, but

ANYTHING to do with them and the

problems or advantages they can create. Honestly I still struggle with them a bit. But I love learning

and love trying to improve. This is certainly one area I need to work on more. So c'mon - fire away.