Re: Oldfast Impressions

Daggers wrote:....and the keys work really smooth! I've used factory cut keys that aren't as smooth as these.

Happy they made it safe & sound... and even happier to hear you like em'.

A Discussion Forum For Anything And Everything For Locksmiths, Hobbyist Lock Pickers, Locksport, Lock Picking, Lockpicks, cutaways, and security. Simply The Best Lockpicking Forum Around!

https://www.keypicking.com/

Daggers wrote:....and the keys work really smooth! I've used factory cut keys that aren't as smooth as these.

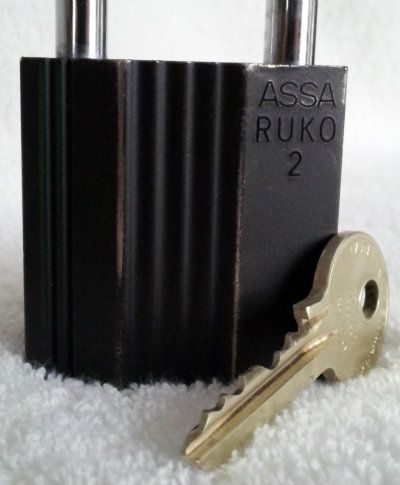

Riyame wrote:Awesome! I bet NNFAK has a certain ASSA that he would LOVE to have a key for.

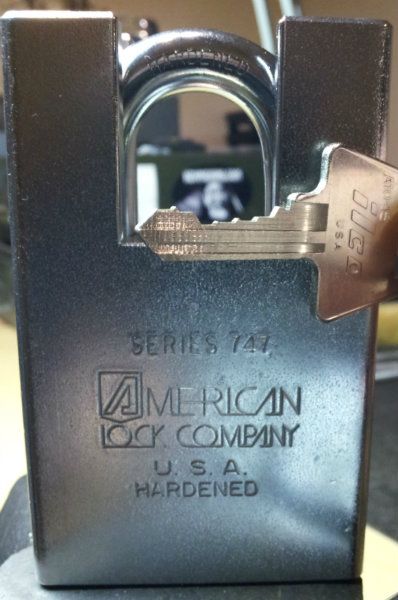

jeffmoss26 wrote:NICE! What do you use to mill out the groove in the key? Also, what are the 2 pin-looking things in the cylinder?

NNFAK wrote:Riyame wrote:Awesome! I bet NNFAK has a certain ASSA that he would LOVE to have a key for.

I almost got the damn thing open the other night...

rai wrote:...not sure what old lock this was, but a core holding rotation restricting pin was once common on some padlock I vaguely remember from the old days, the pin actually was down in the hole beneath the the open end of the shackle, it could be stuck from whatever old graphite and oil or whatever was in there, but you removed the screw that held it in place and just smacked the lock on the bench to get it to move out of there...